Likotoana tsa ho phunya lipekere tsa Carbidee fetohile sesebelisoa sa bohlokoa bakeng sa litsebi tsa litsebi tsa lipekere le ba chesehelang ka ho tšoanang, tse fanang ka nako e telele le ts'ebetso ha li bapisoa le lipekere tsa setso. Leha ho le joalo, ka mefuta e mengata e fapaneng ea lipekere tsa carbide tse fumanehang 'marakeng, ho khetha e ntle ka ho fetisisa e ka ba mosebetsi o boima. Ho o thusa ho etsa qeto o na le tsebo, re hlophisitse tataiso ea mantlha ea ho khetha likotoana tse ntle ka ho fetisisa tsa "carbide" bakeng sa litlhoko tsa hau tsa tlhokomelo ea manala.

1. Ho Utloisisa Mekhatlo ea Carbide Nail Drill

Lisebelisoa tsa lipekere tsa Carbide li entsoe ka thepa e tšoarellang le e tšoarellang nako e telele e tsejoang e le tungsten carbide. Thepa ena e tumme ka ho thatafala ha eona le ho hanyetsa mocheso, e leng se etsang hore e be se loketseng bakeng sa ho kenya lipekere tse nepahetseng, ho bōptjoa le tlhokomelo ea cuticle. Ho fapana le likotoana tsa tšepe tsa setso kapa tsa ceramic, likotoana tsa lipekere tsa carbide li etselitsoe ho mamella ts'ebeliso e tsoelang pele ntle le ho thella kapa ho chesa, ho fana ka kalafo e boreleli le e sebetsang hantle.

2. Nahana ka Grit

Likotoana tsa ho cheka lipekere tsa Carbide li tla ka maemo a fapaneng a grit, a khethollang ho ba mahoashe le ho tšoaneleha bakeng sa kalafo e fapaneng ea manala. Li-grit bits tse tlase (mohlala, 80-120) li loketse ho tlosa li-gel le lisebelisoa tsa acrylic, ha li-grit bits tse phahameng (mohlala, 400-800) li loketse ho hloekisa lipekere tsa tlhaho le ho etsa likhahla tse boreleli. Ho utloisisa lintlha tsa grit ho tla u thusa ho khetha karolo e nepahetseng bakeng sa mekhoa e khethehileng ea lipekere.

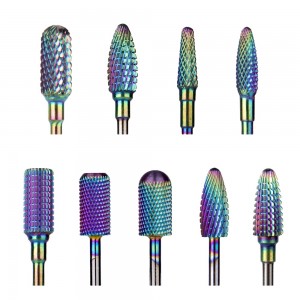

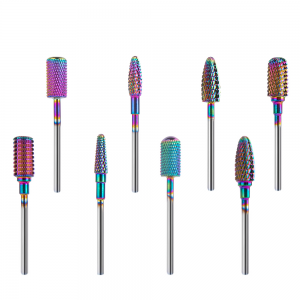

3. Sebopeho le Moralo

Sebopeho le moralo oa likotoana tsa lipekere tsa carbide li bapala karolo ea bohlokoa ts'ebetsong ea tsona le ho feto-fetoha ha maemo. Libopeho tse tloaelehileng li kenyelletsa khoune, moqomo, lelakabe le nale, e 'ngoe le e 'ngoe e sebeletsa merero e fapaneng joalo ka ho hloekisa cuticle, ho buffing holim'a metsi, le sebopeho se nepahetseng. Ho phaella moo, nahana ka bolelele le bophara ba likotoana, kaha lintlha tsena li laola bokhoni ba tsona le ho fihla libakeng tse thata.

4. Ho tšoarella le Tlhokomelo

O mong oa melemo ea mantlha ea likotoana tsa lipekere tsa carbide ke ho tšoarella ha tsona ka mokhoa o ikhethang, empa tlhokomelo e nepahetseng e bohlokoa ho lelefatsa bophelo ba tsona. Sheba likotoana tse nang le lilaete tse sa jeng le libaka tseo ho leng bonolo ho li hloekisa ho thibela mafome le masalla a mangata. Ho feta moo, nahana ka ho tsetela tharollong e nyane ea ho hloekisa le setshelo sa polokelo se inehetseng ho boloka bohale le bots'epehi ba likotoana.

5. Ho lumellana le Shank Size

Netefatsa hore likotoana tsa lipekere tsa carbide tseo u li khethang li lumellana le mochini oa hau oa ho phunya manala. Boholo ba li-bits tse tloaelehileng li na le boholo ba shank ea 3/32 inch (2.35mm), e tsamaellanang le mechine e mengata ea ho phunya manala. Leha ho le joalo, ho bohlokoa ho netefatsa ho lumellana ho qoba mathata leha e le afe ka ho lekana kapa ts'ebetso.

6. Maikutlo le Likhothaletso

Pele o reka, iphe nako ea ho bala maikutlo a bareki le ho batla likhothaletso ho tsoa ho litsebi tse nang le boiphihlelo tsa lipekere kapa batho ba chesehelang chelete. Maikutlo a 'nete le temohisiso li ka fana ka tlhaiso-leseling ea bohlokoa mabapi le ts'ebetso, ho tšoarella, le boleng bo akaretsang ba likotoana tse khethehileng tsa ho phunya lipekere tsa carbide.

Qetellong, ho khetha lisebelisoa tse ntle ka ho fetisisa tsa ho cheka lipekere tsa carbide ho kenyelletsa ho nahana ka grit, sebōpeho, nako e telele, tlhokomelo, le ho lumellana, le ho bokella maikutlo ho tsoa ho basebelisi ba bang. Ka ho hlahloba lintlha tsena ka hloko, u ka khetha ka kholiseho likotoana tsa ho phunya lipekere tsa carbide tse fihlelang litlhoko tsa hau tse khethehileng tsa tlhokomelo ea manala le ho phahamisa boiphihlelo ba hau ba kalafo ea manala.

Nako ea poso: Mar-07-2024